Blade manufacturing

Higher yield — higher process reliability — less cost

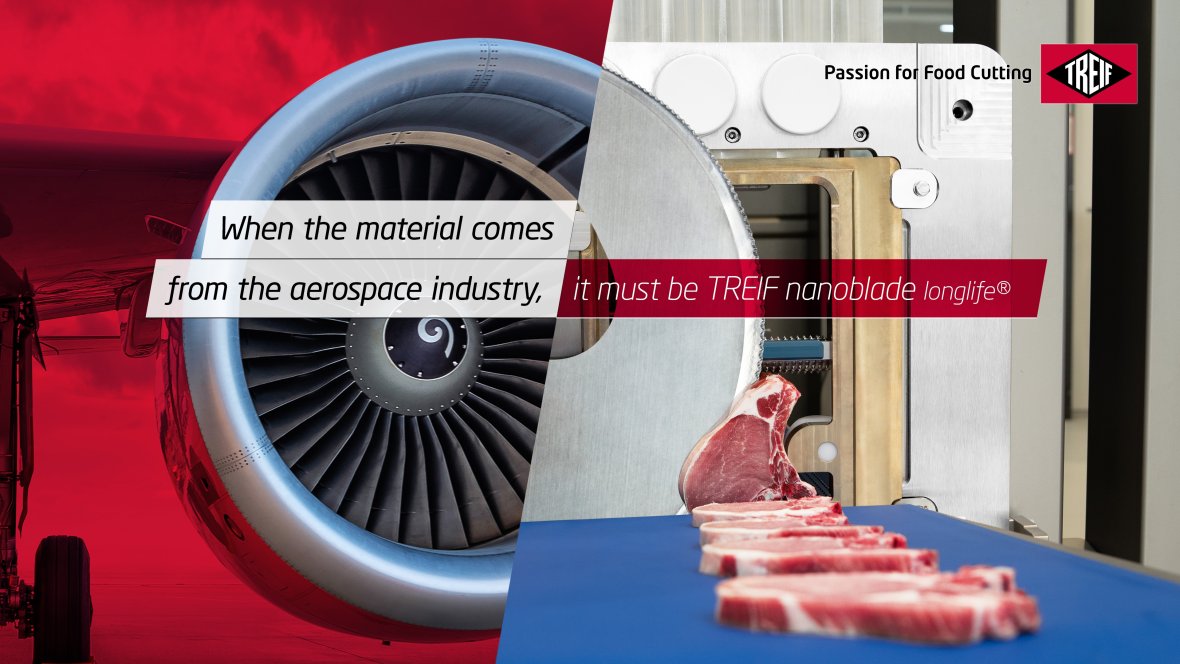

TREIF nanoBlades: Use 100 % of your cutting machine‘s potential by using the optimum blade. TREIF develops and manufactures machine and blade as one unit — the only way to achieve an optimum cutting result.

And — at the end of the day, you also save cost. TREIF blades are designed for a long service life. High quality steel, complex manufacturing processes on the highest level including sophisticated mechanisms for engraving the blade and a sharpening service that focuses on fast sharpening as well as on quality and a long service life of the blades — all this speaks for itself.

Your benefits at a glance:

• Ideal cutting conditions, consistent cutting quality due to best possible interaction between TREIF quality blades and TREIF machine

• Best possible use of your cutting machine‘s potential and consequently higher yield

• High degree of process reliability

• Long cutting-edge life and long service life of the blade through use of high-quality blade steel, lowest possible tolerance limits in manufacturing and professional, low-wear sharpening and regrinding

• No risk of damage or additional wear on other machine parts (e.g. bearing, cutting frame) through non-expert blade treatment

• Sharpening devices for TREIF blades (HS models)